AcuWorkorder - Light Manufacturing

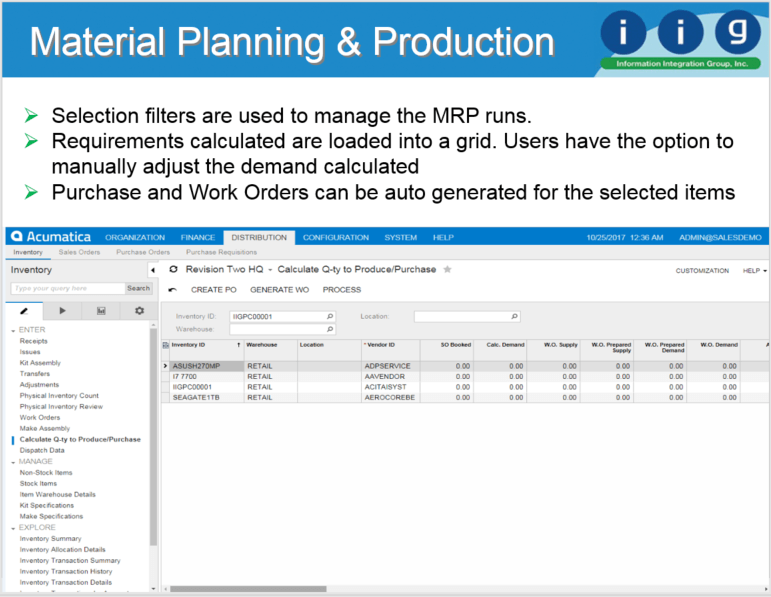

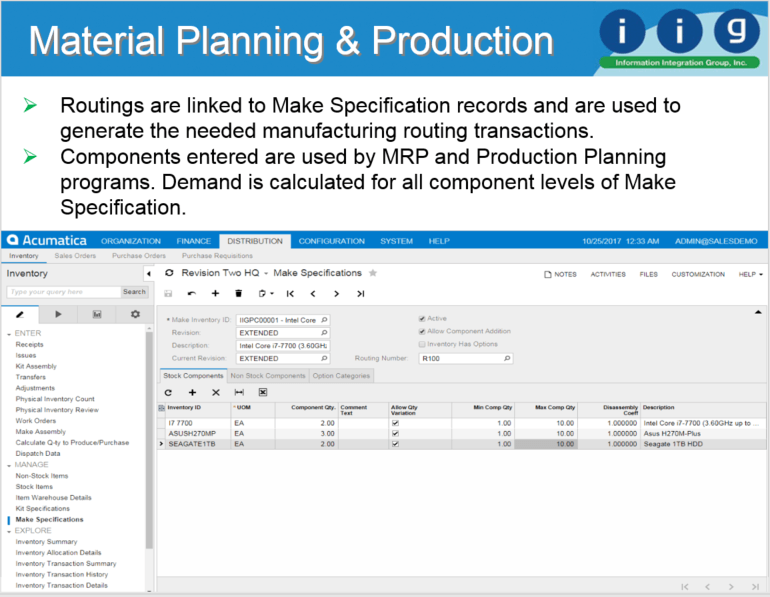

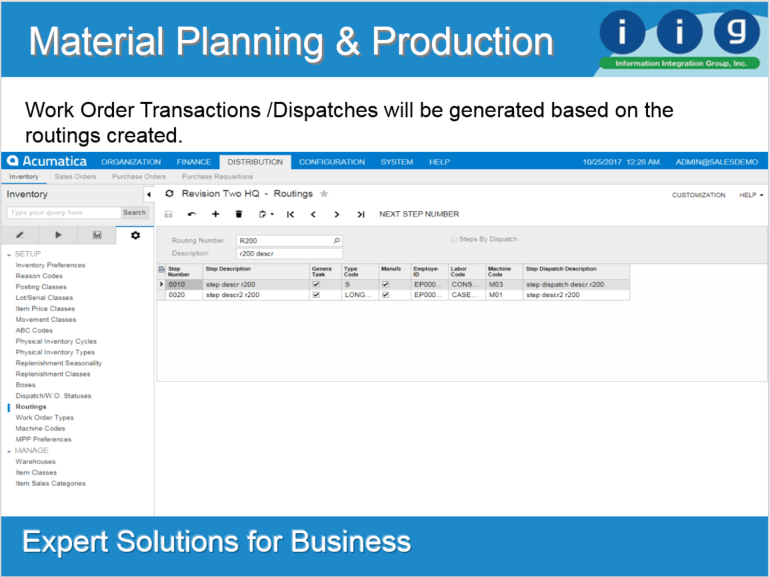

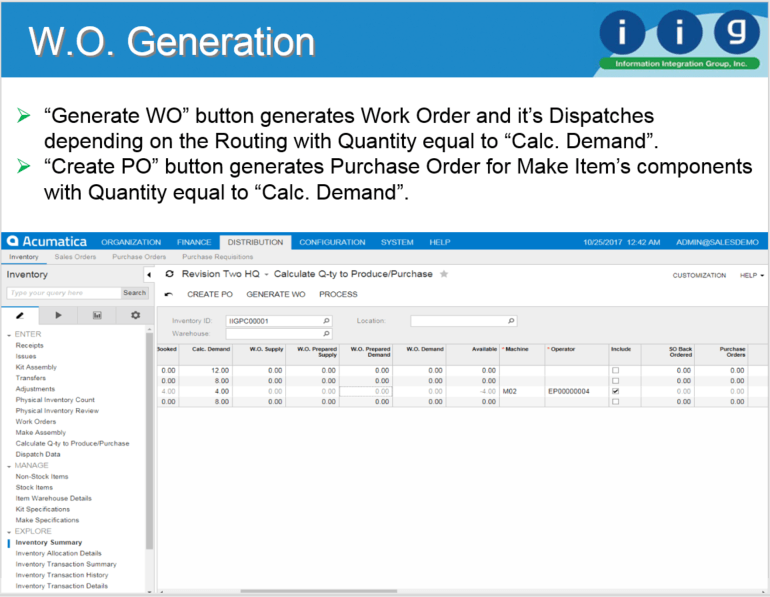

Acuworkorder adds to production capabilities of Acumatica by allowing users to view for each item, calculated requirements by week for all BOM levels based on replenishment parameters, “What-if” scenarios, and existing transactions (all or based on entered ship date). Users can create work orders, purchase orders or transfer sales orders based on the finalized demand. Manage each step of the manufacturing process using routings linked to production items. Group components and issue to production during different steps in the manufacturing process, backflush or when releasing work orders. Provides the ability to load entered labor and material into sales order transactions for job shop orders. Load components into MFG transactions using scanners and click on start and end time to capture labor used for each manufacturing step. Track quantity required for, and on work orders. Move components to Production location for work orders released to production. Create Kit Assembly transactions for closed work orders.

Create Work Orders based on Demand

Track Inventory in Production

Generate Work Orders from Sales Orders

Scheduling Board Views

Auto P.O. or Transfer S.O. Generation

Create Work Order for Phantom Bills

Track Q/C Notes and Activities

Manage Outside Processes using Routing steps

Yield and Scrap Percent Tracking

Manage Work Orders using existing reports

User Defined Option Categories

Support for Process MFG Work Orders

Overhead Allocation

Post WIP to GL for Production Work Orders

Key features

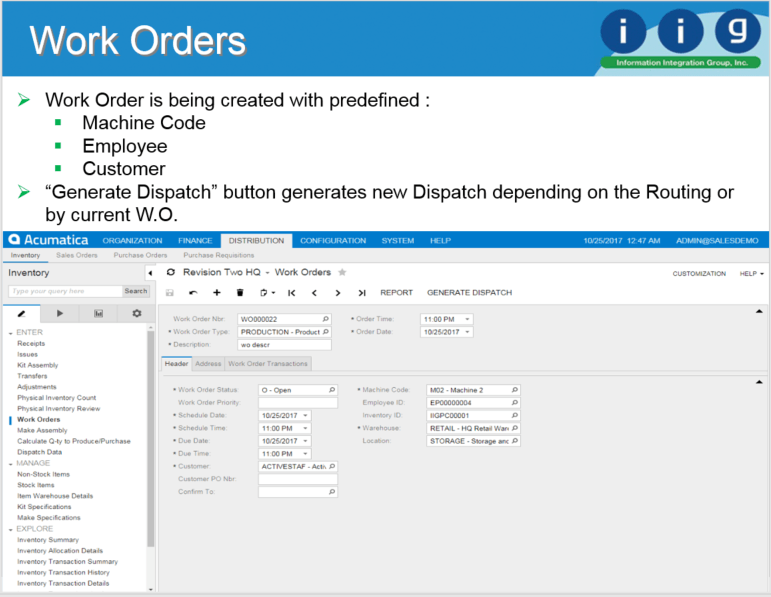

- Ability to generate Work Orders for products to be manufactured

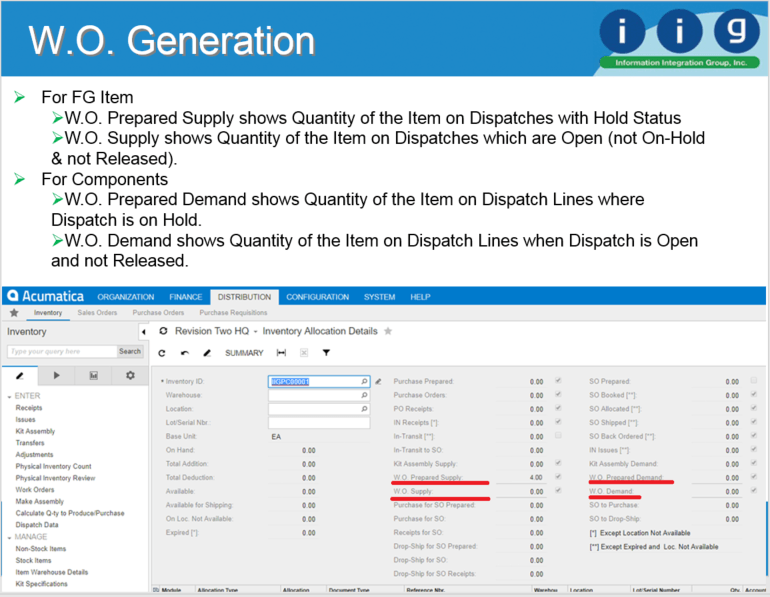

- Ability to track quantity on WO and REQ for WO for generated work orders

- Ability to schedule work orders

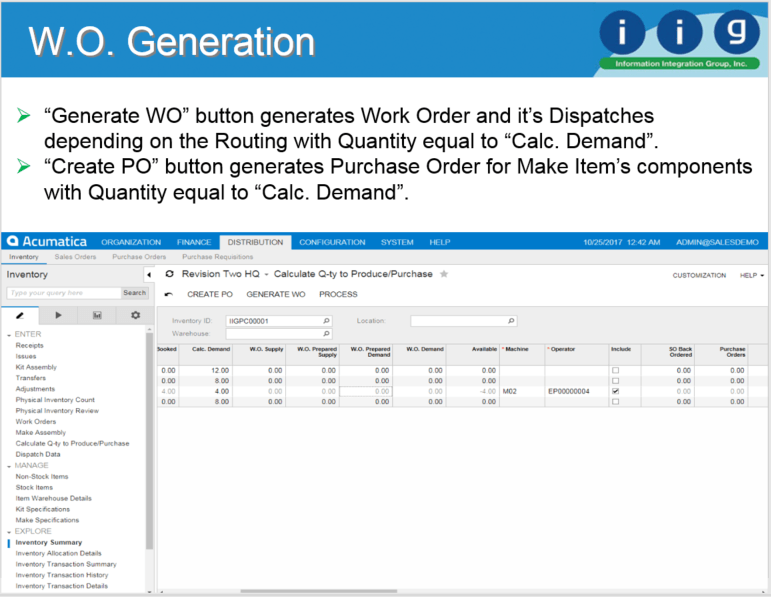

- Ability to generate Purchase Orders for material shortages taking into account created work orders

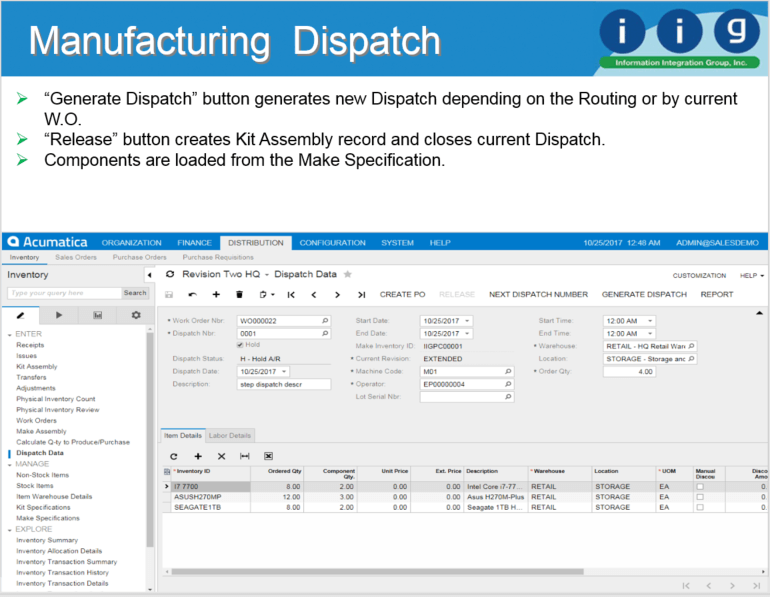

- Ability to create Routings to manage the production process

- Post inventory to WIP by routing steps

- Create and link routing to kit specifications

About Information Integration Group

Information Integration Group, Inc. (IIG) has over 25 years of experience advising and supplying small and medium sized businesses with the proper ERP systems and custom software solutions to fit their company’s needs. We have a talented group of consultants and professionals that can take a comprehensive look at the needs of your business and make sound recommendations based on their findings. Contact us today to get started and take advantage of Cloud solutions to grow your success. We specialize in Acumatica as well as the corresponding Software Enhancements known as Acuboost.

Resources

Customer Reviews

Our company does mostly one-piece orders (job shop) with some large runs as well. Most ERP manufacturing modules are overkill and create too much burden to be really useful for us. We needed an easy-to-use solution that was powerful enough for all types of manufacturing.

AcuWorkOrder light manufacturing is very powerful yet easy to use for our different manufacturing jobs. We were able to go reduce our manufactured parts from 60,000 in our old system to under 5,000 by using the Bill Options feature to create customized BOM's based on options chosen. It is easy to create and then follow work orders through the system. Inventory and purchase orders are streamlined with the Calculate Quantity to Produce screen which tells me about my demand throughout Sales orders and Work orders. I highly recommend AcuWorkOrder.

There are a lot of most valuable features. Most valuable is the ability to easily create work orders from Sales orders and then easily order raw materials for Just in time delivery. The creation of BOM's (kit specifications) and routings is fast and straight forward. The Bill Options feature allows us the flexibility of a make to order, bespoke product based on options chosen without having to have hundreds of thousands of SKU's for every single option combination.

When we started with Acumatica we went with JAMS MFG Module (now Acumatica's MFG Module). We found that based on our production needs we didn't need such a robust MFG Module. We did our research and found IIG’s Lite MFG Module.

We’ve been using it for about four years now and it’s perfect for what we do. IIG was very accommodating to customizations we wanted and suggested best practice solutions for us. We’ve created customizations in many screens, work order, BOM, QCPP/MRP and others. We are also very happy with how they continue to improve the product annually. To me this shows that IIG is dedicated to making sure its product stays current with what’s on the market in manufacturing. Support is very important to us, I’m glad to say that IIG’s support is definitely top of the line. Replies to support emails are timely and you can always get someone on a call if need be.

IIG’s “Work Order Management” which is part of our Acumatica allows us to see before hand what raw materials are required, how much we would need to have on hand before we can plan the production. WHAT IF function allows us to plug and play with data. We generate Work Orders to fulfill our demand for current Sale Orders or to build the inventory to a specific level. We have ability today to ensure that only pre-approved components will be taken to a production.

Most valuable part of IIG's WO module is that we have our QC notes integrated with our production. We are now able to trace every roll we make and have the whole production history attached to it.

IIG's WO module allows us to communicate every step of production between our employees in the ERP system.

MFG report provides valuable yields, historical costs per each production as well as traceability with the Work Order itself. Scheduling feature allows to visualize our day and night shifts production loads, trace quality issues per shift.

We use WOP for creating BOM's and managing our inventory flow. The WOP system was also to put in production notes for our assembler’s and QA personnel to follow. The system does an excellent job of maintaining inventory accuracy as it forces us to build, disassemble as we are trying to move through the process instead of after the fact as we had done in the past. This is keeping our inventory more accurate than ever before.

In certain areas there are a few too many clicks required to process a transaction, but otherwise very good solution.