According to the 2023 BDO Manufacturing CFO Outlook Survey, 69% of manufacturers are thriving despite an uncertain economy. This is encouraging news, but manufacturers are dealing with the fact that pandemic-induced challenges are not only still alive but also shaping today’s top four manufacturing trends:

- Conquering supply chain disruptions.

- Taming economic headwinds.

- Embracing technology.

- Combating talent shortages.

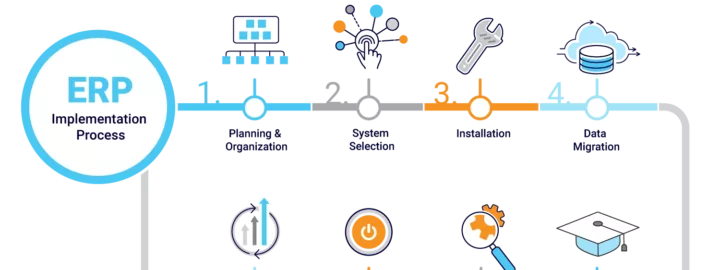

Today, I’ll explore these trends and examine how manufacturers can benefit from them—with the help of modern manufacturing management software through a comprehensive ERP solution.

Manufacturing Trend #1: Conquering Supply Chain Disruptions

Supply chain disruptions have become a constant over the last few years. In fact, 70% of the CFO respondents to the BDO survey believe supply chain disruptions “pose some risk or a significant risk to their business…,” and the higher cost of goods sold (COGS) is forcing manufacturers to offset these challenges by:

- Improving supply chain visibility.

- Raising prices for customers.

- Moving production to geopolitically close U.S. allies.

- Finding alternative suppliers.

And add onshoring (also known as nearshoring or reshoring) to the list. Onshoring reduces a manufacturer’s dependency on international suppliers by establishing ties with local suppliers. This stimulates the local economy and secures the manufacturer’s supply chain against international conflicts.

But companies need technology to make these changes happen. Manufacturing ERP solutions provide centralized, updated, real-time data that companies can use to forecast and evaluate their inventories, material requirements, and logistical needs. The right ERP system will give a manufacturer clear visibility into its resources, planning capabilities for delivery and production schedules, and analytical tools for assessing operational needs and making fast, strategic decisions.

Manufacturing Trend #2: Taming Economic Headwinds

Though there is growth in the manufacturing sector, high inflation and concerns over a possible recession still plague every industry.

Economic factors of this magnitude are outside manufacturers’ control, but they can mitigate the effects of these factors by centralizing their companywide data in one strategic system. A manufacturing ERP system will help them:

- Anticipate and adjust prices to keep up with economic fluctuations.

- Simplify return and exchange processes.

- Track and reduce costs.

- Eliminate manual data entry and improve productivity.

Manufacturing management software can also help a business identify areas that can be streamlined, debts that can be paid, and revenue sources that can be diversified—all adding up to a stronger financial position.

Manufacturing Trend #3: Embracing Technology

Advanced manufacturing technologies, such as artificial intelligence (AI), machine learning (ML), virtual reality, 3D printers, the Industrial Internet of Things (IIoT), robots, cobots, and more, are infiltrating the manufacturing industry. In its 2023 Manufacturing Industry Outlook Report, Deloitte notes that “Continued investments in advanced manufacturing technologies can help develop the…agility” manufacturers need to boost resilience and mitigate risk.

Investing in manufacturing management technology equips companies with the skills and information they need to remain efficient and competitive. The right technology for today’s manufacturers will come equipped with AI and ML capabilities that are ready to go, straight out of the box.

The right ERP solution should also use open APIs to seamlessly integrate with vital third-party applications and specialized technologies—enabling businesses to connect, monitor, and manage every facet of their operations from a single system.

Manufacturing Trend #4: Combating Talent Shortages

During the pandemic, manufacturing output and hours worked significantly declined. Companies had no choice but to lay off workers, and this forced firing situation, coupled with the Great Resignation and a surge in Baby Boomer retirements, meant the manufacturing industry suddenly had a bare-bones workforce.

At the time, having fewer employees was a sustainable situation, but it has quickly become a concern as manufacturing growth has increased. Manufacturers seeking skilled workers, or workers who can be trained successfully, are coming up short.

Thankfully, there are methods for beating the manufacturing labor shortage, such as hiring talented women to fill roles historically filled by men and offering robust incentives that speak to the younger generation (e.g., flexible schedules, remote or hybrid work options, and a sustainable organizational mission). But manufacturers can also combat the labor shortage by implementing modern manufacturing management software.

Manufacturing management software is attractive to younger workers who are digital natives, and it helps companies automate manual processes—reducing the number of employees they need in the office and on the shop floor. In addition (and very importantly), a manufacturing ERP solution helps businesses forecast labor needs accurately and allocate resources efficiently.

Letting Acumatica Help

It seems these manufacturing trends will be here for the next several years, and companies should equip themselves with innovative manufacturing management software, like Acumatica, if they want to successfully address these trends now and in the future. Acumatica’s playbook, “Prepare for the Factory of the Future with Acumatica Manufacturing Edition,” perfectly summarizes why Acumatica is the right choice:

Acumatica Manufacturing Edition is designed for make-to-stock, make-to-order, batch process, and project-centric manufacturers. Acumatica provides unparalleled manufacturing depth with an extensive suite of connected manufacturing business applications for production, estimating, engineering, material planning, scheduling, and product configuration.

Download this free resource and Acumatica’s other playbook, “Mitigate Supply Chain Disruption with Acumatica Cloud ERP,” to learn more about Acumatica’s award-winning cloud ERP software. Our experts are standing by to answer any questions and/or to help schedule a demonstration.

Canada (English)

Canada (English)

Colombia

Colombia

Caribbean and Puerto Rico

Caribbean and Puerto Rico

Ecuador

Ecuador

India

India

Indonesia

Indonesia

Ireland

Ireland

Malaysia

Malaysia

Mexico

Mexico

Panama

Panama

Peru

Peru

Philippines

Philippines

Singapore

Singapore

South Africa

South Africa

Sri Lanka

Sri Lanka

Thailand

Thailand

United Kingdom

United Kingdom

United States

United States