According to the National Association of Manufacturer’s Outlook Survey, 74% of manufacturers see attracting and retaining a quality workforce as a top business challenge. And as we near the end of Q2 2023, the manufacturing labor shortage continues to dominate conversations within the industry.

Start with the workforce disruptions caused by the pandemic, add a large number of retiring manufacturing workers and a dearth of skilled workers to replace them, and you have a labor deficit that’s difficult to overcome. In fact, a study by Deloitte and The Manufacturing Institute reveals that 2.1 million manufacturing jobs could be unfilled by 2030, “impacting everything from productivity to innovation and competitiveness to GDP.”

Concerning? Yes. But to beat the manufacturing labor shortage, companies need to employ two specific initiatives: attracting and retaining talent from a wider pool of candidates and investing in modern manufacturing software.

Let’s look at each strategy.

Finding New Workers (and Keeping Them Happy)

With Baby Boomers retiring every day, manufacturers need to fill those positions quickly, but finding people willing or able to do so is challenging. Deloitte cites evolving career expectations, low interest in the industry, and insufficient education and training as the top causes of the skills shortage. To overcome these obstacles, manufacturers need to rethink the power of incentives, like flexible schedules that prioritize work/life balance, remote and hybrid work options, and a strong commitment to a socially and environmentally responsible culture. Incentives like these draw skilled workers and encourage long-term employee loyalty.

Manufacturers also need trained—or trainable—employees. So, they should consider expanding their talent pools to include the untapped potential of a critical segment: women.

According the U.S. Department of Commerce, women “only make up about 30% of the 15.8 million people employed in manufacturing industries.” But a 2023 joint report by Xometry and The Women in Manufacturing Association (WiM) finds that women are very interested in entering the manufacturing industry, with 82% of them likely to recommend a career in the sector. Xometry’s news release also reports that “women who pursue an education in Science, Technology, Engineering or Mathematics (‘STEM’) are more than twice as likely as men to choose a career in manufacturing.”

Offering robust incentives and recruiting qualified women can help manufacturers attract a strong, enduring workforce, but the Deloitte study offers one more suggestion: Incorporating companywide diversity, equity, and inclusion (DEI) principles. Says Deloitte: “DEI has been proven to drive business performance and innovation. Not only do companies with a diverse workforce experience increased productivity and better organization management, they have been shown to have a competitive advantage in the industry.”

Investing in Manufacturing Software

Just as incentivizing current and potential workers can ease the burden of understaffing, so, too, can investing in manufacturing software that empowers employees to use their skills and training most effectively. The manufacturing industry has historically been slow to adopt new technologies, relying instead on machines and a skilled labor force to transform raw materials into a quality product.

But things are changing.

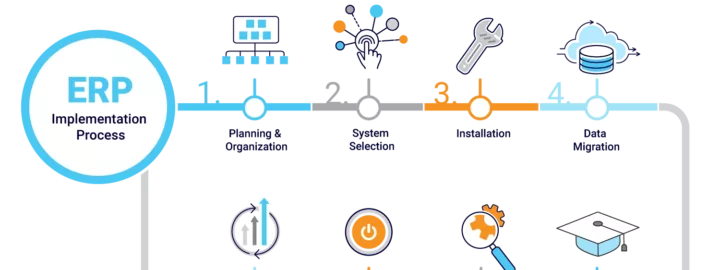

A recent SelectHub article notes that many manufacturers are adopting software to streamline their practices, highlighting artificial intelligence (AI), the internet of things (IoT), and 3D printing as specific examples. But manufacturing ERP solutions are growing in popularity.

Manufacturing ERP solutions provide the innovative features and functionalities companies need to become efficient, profitable businesses, helping them manage data, monitor inventories, support supply chain operations, improve reporting and analytics, and more—all from a single, centralized platform.

To address workforce challenges, manufacturing ERP solutions automate tasks previously accomplished with manual labor, either in the office or on the shop floor (e.g., entering data, monitoring job progress, and detecting bottlenecks before they occur). Such automation reduces the number of required employees, increases collaboration, and makes it easier for employees to be more productive, efficient, and creative. Cloud-based ERP solutions offer on-the-go connectivity, which means employees—whether in the office, at home, or in the field—can access the most current data at any time via any web-enabled device.

Manufacturing ERP solutions supply accurate, real-time data that companies can use to forecast labor needs and allocate resources. And workers within the Gen X and Millennial demographics—digital natives—are attracted to modern, intuitive technology that makes their jobs easier.

So, across the board, advanced ERP solutions can fill the manufacturing industry’s current needs.

Selecting the Right Manufacturing Software

The manufacturing labor shortage can be alleviated by offering positive incentives, recruiting from a wider talent pool, embracing DEI standards, and implementing modern manufacturing software, like Acumatica’s award-winning cloud ERP solution.

Acumatica’s Manufacturing Management software delivers real-time insights from every department across a company, gives users complete control over production, and supports multiple manufacturing methodologies. It also offers manufacturers a 360° view of the entire business, so they can work smarter with fewer people.

To learn more about beating the manufacturing labor shortage, download Acumatica’s complimentary Solution Brief, “Proven Practices for Overcoming Today’s Labor Shortage,” and our eBook, “Defeat the Labor Shortage by Empowering Your Workforce with Modern Cloud ERP.” Each resource delivers deep insights into the benefits manufacturing software can bring to your business.

Our experts are standing by to answer any questions and/or to schedule a demonstration.

Canada (English)

Canada (English)

Colombia

Colombia

Caribbean and Puerto Rico

Caribbean and Puerto Rico

Ecuador

Ecuador

India

India

Indonesia

Indonesia

Ireland

Ireland

Malaysia

Malaysia

Mexico

Mexico

Panama

Panama

Peru

Peru

Philippines

Philippines

Singapore

Singapore

South Africa

South Africa

Sri Lanka

Sri Lanka

Thailand

Thailand

United Kingdom

United Kingdom

United States

United States