Comparing Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) Solutions

Managing inventory is foundational to every manufacturer, retailer, and distributor—but it’s also one of the biggest challenges they face. Where do the resources and supplies needed to make a product come from? How and where are these resources and the finished products stored in the warehouse? And how does the inventory go from being produced to purchased and from being packed to shipped?

Fortunately, today’s businesses have a leg up on their predecessors when it comes to managing these complexities. Modern technology eliminates the error-prone paper and spreadsheet warehouse management techniques of the not-so-distant past.

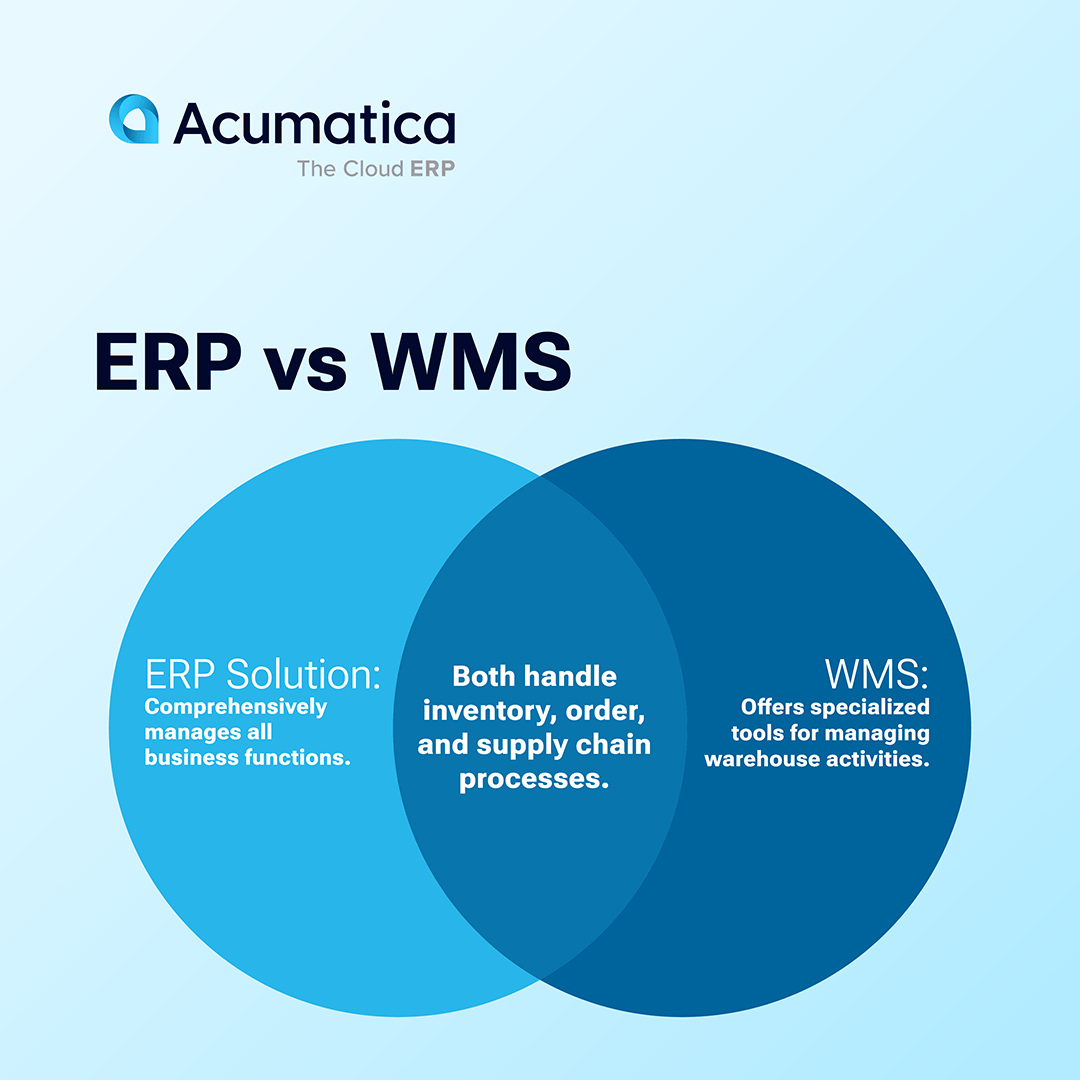

Two prime examples of such advanced technologies are Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) solutions. While each delivers warehouse management features and benefits, they have important differences.

The key differences between a WMS and an ERP solution lie in their scopes, functionalities, and inventory optimization capabilities. ERP is designed to integrate various business functions across an organization, providing an all-in-one platform for managing finance, human resources, supply chain, and warehousing. In contrast, WMS is a specialized tool dedicated exclusively to managing typical warehouse operations.

What is a Warehouse Management System (WMS)?

Businesses use WMS to support critical warehousing processes, ranging from inventory management (e.g., receiving, storing, and tracking) and the pick-and-pack process to analyzing operational efficiencies and collaborating with suppliers, transportation vendors, and team members.

Key Features and Benefits of a WMS

The primary function of a WMS is to facilitate a smooth supply chain and inventory management experience that results in a solid bottom line and happy consumers. To ensure this outcome, WMSs often offer these key features:

- Tracking and tracing of inventory movement and storage—including in-stock/out-of-stock information.

- Mobile and barcoded pick lists.

- Integration with digital scales to automatically weigh shipments and print labels and packing slips.

- Support for shipment costs, scheduling, and tracking.

- Automatic shipment status notifications for customers.

- Analytics that measure warehouse and labor efficiency.

- Reporting functionality that aggregates warehouse-wide data.

What is an Enterprise Resource Planning (ERP) Solution?

An ERP solution has broader functionality than a WMS. For example, while a WMS is designed to specifically manage warehouse logistics, an ERP solution gathers data from every department—including warehouse management—into its centralized database. Companywide processes are consolidated in a single system, which eliminates data silos and disconnects across departments. With an ERP solution, all team members can easily collaborate and access the information they need to do their jobs.

Core Modules of ERP Solutions

Most ERP systems provide core modules, including:

- Inventory Management

- Order Management

- Sales and Purchase Order Management

- Accounts Receivable and Payable

- Payroll Management

- Tax Management

- Project Accounting

- Reporting and Data Analysis

- Warehouse Management

- Customer Relationship Management (CRM)

- Project Planning and Resource Management

Many of today’s ERP systems also rest on open platforms that enable seamless integrations with additional industry-specific modules and with external, third-party applications.

Advantages of an ERP Implementation

An ERP implementation brings with it a number of advantages. One of the biggest is the improved efficiency and productivity fostered by streamlined workflows, reduced waste, and advanced automation capabilities. Other advantages are real-time data and reporting, which enable team members to compile and analyze business information quickly and easily—making fact-based, strategic decisions.

ERP users also cite:

- Enhanced collaboration due to everyone working with the same information.

- Cost savings from increased efficiency and better communication.

- Improved customer outcomes through more personalized, data-driven customer service.

- The ability to grow rapidly while operating as a well-informed whole instead of as uniformed, disconnected parts.

ERP vs. WMS: What is the Difference?

Businesses asking “what is the difference between ERP and WMS” can look to the systems’ respective functional scopes for the answer.

Functional Scopes

A WMS has the very specific job of managing, automating, and supporting all warehouse processes. Its focus is on tracking inventory, so that inventory can be easily found, accessed, and made available for distribution.

In contrast, an ERP system has a wider assignment: successfully managing the entire business, including warehouse processes, in a single solution. Data from every department is synchronized, and team members can readily use, analyze, and report on that information. ERP systems can also integrate with various modules and applications (even custom-built apps) that support a still wider range of specific uses.

WMS as a Module within an ERP Solution

As previously discussed, modern ERP systems provide extensive functionality, and this often includes a built-in WMS module that ensures all warehousing needs (e.g., receiving, picking, packing, shipping, inventory movement, inventory and warehouse recommendations, labor insights) are taken care of. This way, businesses benefit, not only from WMS features, but also from all other companywide ERP functionalities that cover critical finance, accounting, payroll, sales, reporting, and customer service processes—and beyond.

One connected, end-to-end solution provides real-time data sharing, improved coordination, better resource allocation, optimized processes, and agile decision-making.

Choosing the Right System

An ERP system with an integrated WMS module, like Acumatica, plays a vital role in improving the performance of any business with warehouse and inventory operations.

Acumatica’s Warehouse Management System is an all-in-one solution built to reduce errors, automate data capture, simplify tracking, manage picking, and increase customer satisfaction. It supports:

- Paperless, directed picking.

- Wave or batch picking.

- Barcoded pick lists.

- Packing automation.

- Shipment creation.

- Shipping labels and documentation.

- Customer notifications.

- Stock turnover.

- Physical inventory.

- Bidirectional picking.

- Stock movement.

- Role-based dashboards.

- And more.

Acumatica Cloud ERP is an intuitive, affordable, and comprehensive solution for all your warehousing and front-and-back-office needs. Says customer Ben Leinster, CEO, AFF|group, “For us the power of the Acumatica system is in the WMS and shop floor data collection, the inventory management, and the ability to deliver to a customer and to get things right.”